Current Location: Home>>Products

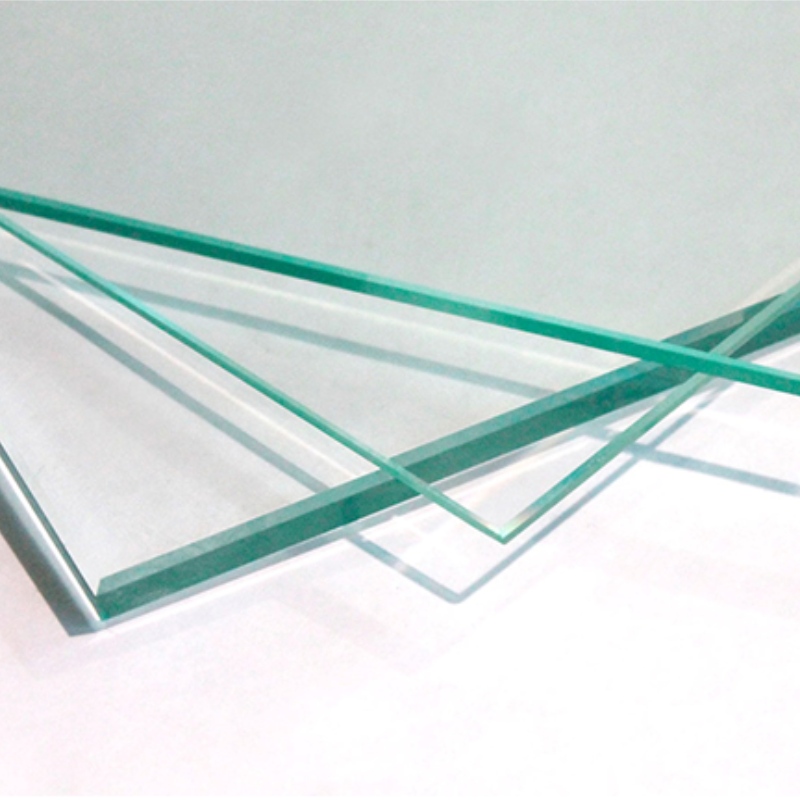

CLEAR FLOAT GLASS

- Hits: 376

- Keywords : clear float glass / annealed float glass / plain glass

Five Advantages Of Products

- excellent quality

- short delivery time

- excellent export service

- strong seaworthy crate package

- sufficient stock

Product Details

all glass materials mixed at batching room, and then go to the melting furnace to become liquid status, then flow out to tin liquids stove, there is one rollers at each side to pull glass forward, we can control the glass thickness by controlling the rollers speed.

After the glass thickness is fixed, it goes to the annealed section, the temperature goes down step by step to become cold finally, and then it will be cut to different sizes, and after quality inspection and packing, go to the warehouse for sale.

For clear float glass, the glass liquid in melting furnace should be clear, then we can get clear float glass. As the materials contains some iron element, clear float glass seems a little greenish.

The usual thickness: 1.6mm, 1.8mm, 2mm, 3mm, 4mm, 5mm, 6mm, 8mm, 10mm, 12mm, 15mm, 19mm etc.

The usual standard sizes: 1830x2440mm, 2134X3300mm, 2134X3660mm, 2440x3300mm, 2440x3660mm.

Usually we pack glass by plywood end cap package. Powder interlayer between glass.

Previous: REFLECTIVE COATED GLASS